Li & Godzik, 2006).Įukaryotic endoglucanase genes from fungi were select-ed.

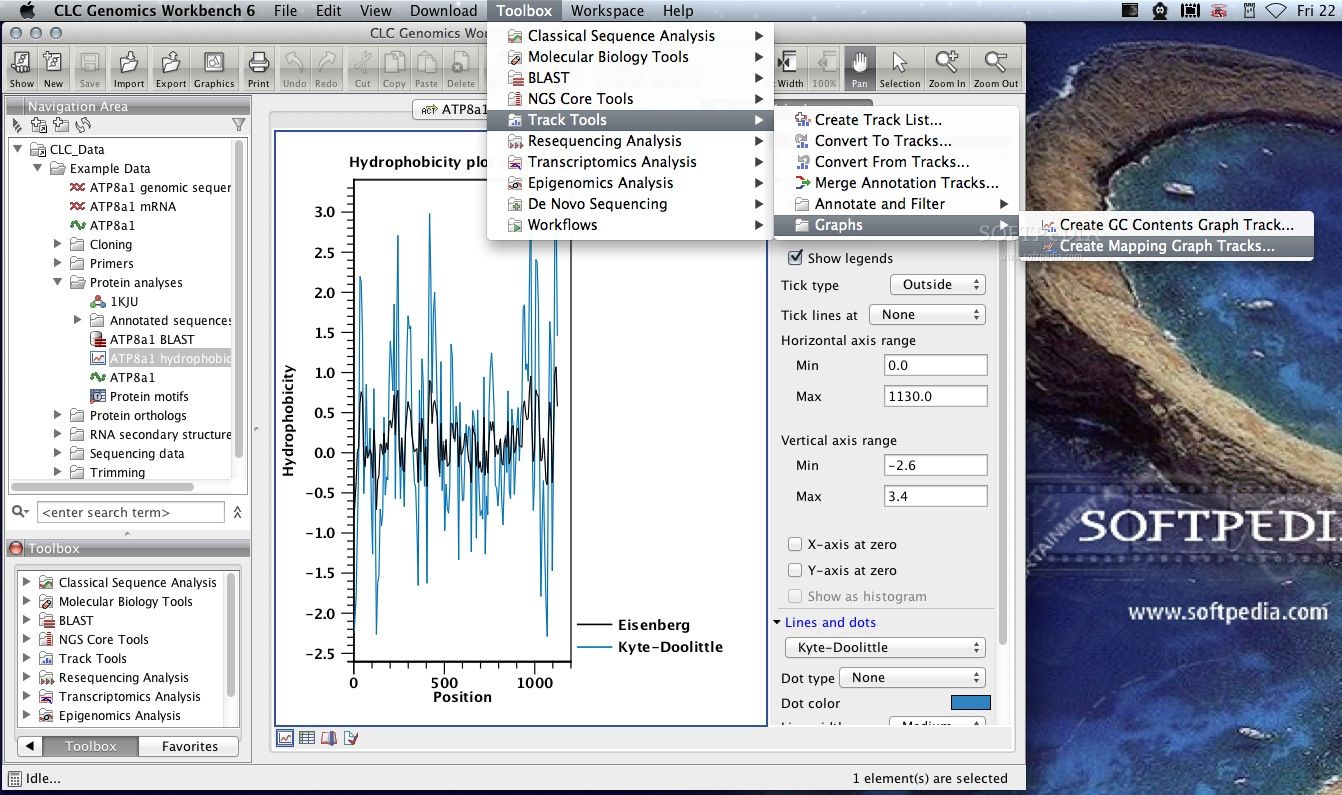

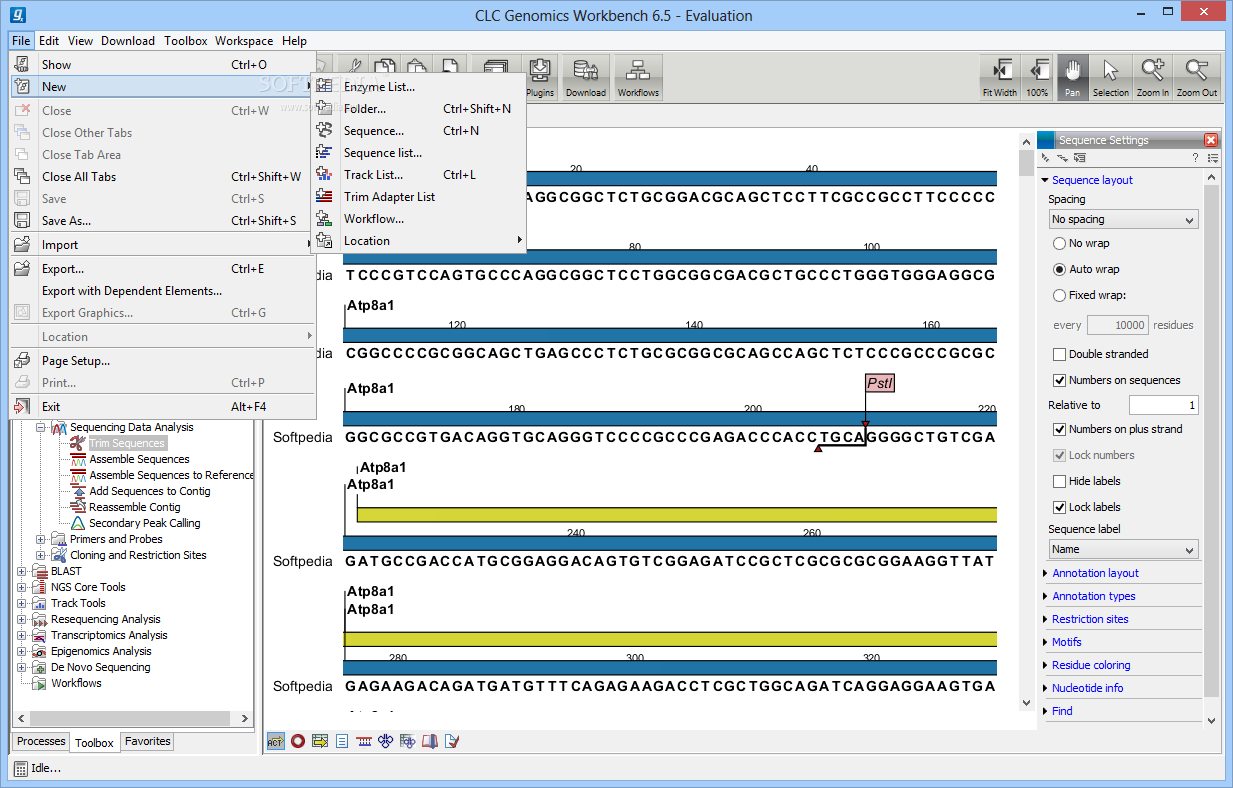

#Ucsf clc genomics workbench software#

Redundant sequences at 100% were eliminated with the CD-Hit software 4.6 (W. Later, domains such alignments were downloaded from Uniprot and each domain function were consulted and downloaded. Subsequently, a search was made of similar sequences to GH families enzymes using the BLAST program (Altschul et al., 1990), identifying functional protein do-mains annotated in Pfam ( ) (Finn et al., 2016) and Prosite ( ) ( Sigrist et al., 2013).

Using these identifiers, the sequences of all the GH enzymes were downloaded from the GenBank, PDB and Uniprot databases ( Berman et al., 2000, Magrane & Consortium, 2011). The identifiers of the GH family were downloaded from the CAZy database containing the endoglucanase enzymes.

MATERIALS AND METHODS Selection of eukaryotic genes encoding lignocellulolytic enzymes coli BL21 (DE3) bacterium for the saccharification of lignocellulose residues, through the modification and cloning of eukaryotic genes of lignocellulolytic enzymes. The objective of this work was to evaluate the expression of endoglucanase fungal gene in E. In these GH families enzymes with the same enzymatic activity are not necessarily gathered, this classification is based on the sequence and structure of the protein, therefore families will understand different enzymatic activities ( Busk, Lange, Pilgaard, & Lange, 2014). Liu, Qin, Li, & Qu, 2013), which can be reduced if genetically modified microorganisms are used, to produce lignocellulolytic enzymes more efficiently in large quantities and in shorter times (Gao et al., 2008 Zelena, Eisele, & Berger, 2014).ĭegradation of lignocellulose is carried out for a cellulolytic system composed of endoglucanase, exoglucanase and celubiosidase (Munjal, Jawed, Wajid, & Yazdani, 201 5).Īccording to the CAZy database, enzymes that degrade cellulose and other polysaccharides from plant cell wall, are classified into the glycose hydrolase families. Of these three methods, the most promising by specificity and high recovery of glucose is enzymatic hydrolysis, with the disadvantage that the production of enzymes has high costs ( Gao et al., 2008, G. Lignocellulose is currently hydrolyzed by mechanical breakdown followed by acid, alkaline and / or enzymatic hydrolysis ( Persson, Tjerneld, & Hahn-Hágerdal, 1991 Cuervo, Folch, & Quiroz, 2009 Castillo et al., 2012). Taking into account the price of the gallon of ethanol of U$ 3.07 Colombian pesos (COP) (August 2018), approximately U$ 120,240,897 would be obtained (Sánchez Riaño et al., 2010). If waste from Colombian industries such as citrus juice and rice husks were used, 136,045,500 L and 12,200,000 L of bioethanol would be obtained annually (Sánchez Riaño et al., 201 0). Colombia has a high production of lignocellulose, which can be used to produce bioethanol. The lignocellulosic waste is composed of cellulose, hemi-cellulose and lignin and around 200,000 million tons are produced annually (Medina-Morales, Lara-Fernández, Aguilar, & de la Garza-Toledo, 2011 Saini, Saini, & Tewari, 2015). However, be-cause bioethanol is traditionally manufactured with lignocellulose from crops such as corn, the price of food tends to increase, which becomes a reason to focus efforts on the use of lignocellulose from lignocellulosic waste for its production.

It is possible to mix gasoline with bioethanol to offer savings in CO2 emissions of at least 50% compared to fossil fuels (Hernández Rodríguez & Hernández Zárate, 2008). Bioethanol can replace part of the consumption of traditional fuels such as oil or coal.

0 kommentar(er)

0 kommentar(er)